Experience.

Capability.

Downstream Process Purification Development from a Leading US-based CDMO

As a trusted US-based CDMO, GBI delivers end-to-end solutions for downstream process purification development, supporting clients through preclinical, clinical, and commercial stages of biologics manufacturing. With decades of experience and an integrated approach across development, manufacturing, QA/QC/RA, and purification teams, we offer robust, scalable, and cost-effective downstream solutions tailored to biologic therapies and diagnostic applications.

We are proud to be one of the top CDMO companies in the US. We help biopharma innovators accelerate timelines while ensuring cGMP compliance, product quality, and regulatory readiness.

Contact UsDownstream Processing Expertise Across Diverse Biologics

GBI provides full downstream purification capabilities for a wide range of complex biologics, including:

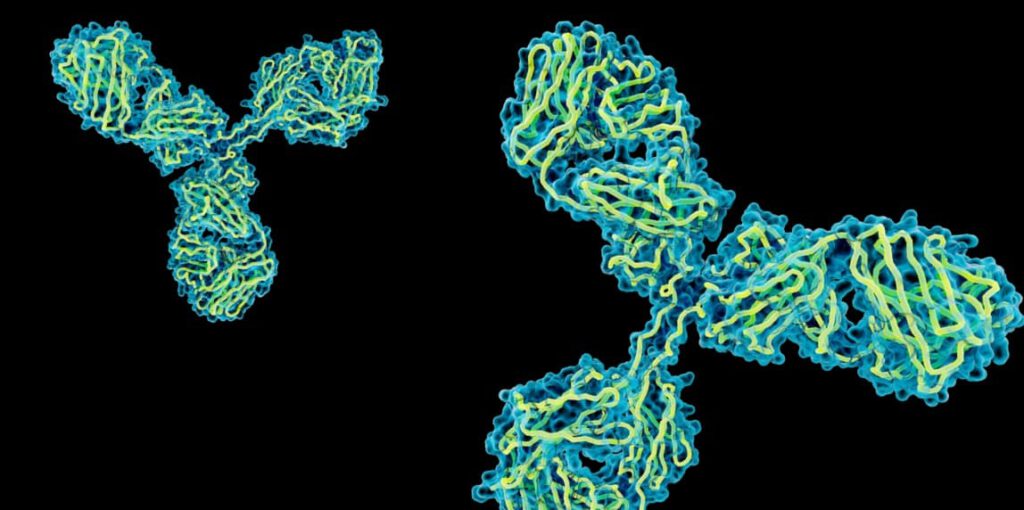

- Monoclonal and polyclonal antibodies and antibody fragments

- Antibody fusion proteins and Fc-fusion proteins

- Multispecific antibodies

- Growth factors and cytokines

- Exosomes and extracellular vessicles

- Enzymes

- Bio-conjugates including photoimmune, radioimmune, oligonucleotide, vaccine and other ligand conjugates’

- Other recombinant proteins

We develop non-GMP materials for proof-of-concept (preclinical), tox animal study and product characterization. We also support cGMP manufacturing of mammalian cell culture-derived biologics for toxicity studies, first-in-human (FIH) trials, late-phase clinical and commercial programs.

The new 2,000 L single-use manufacturing suite that will launch in mid-2023 as part of our upgraded cGMP facility will expand our capabilities into commercial manufacturing for larger scale projects.

Expanding cGMP Manufacturing Capacity

With the launch of our new 2,000 L single-use manufacturing suite as part of our upgraded cGMP facility, GBI now supports commercial-scale drug product development and downstream purification for late-stage and high-volume projects. This facility further strengthens our position among leading CDMO US providers.

Flexible Downstream Suites with Advanced Technology

Our downstream purification suites are customized for each project and outfitted with best-in-class systems, including:

- ÄKTA™ systems (gradient and step elution) for small- and large-scale runs

- ÄKTA™ ready for scalable purification with 500–600 L/h operating flow rates

- ÄKTA™ process for scale up purification suitable for GMP-regulated manufacturing with option for various automation solutions for diverse process control requirements.

- Tangential flow filtration (TFF) using flat plate and hollow fiber formats

- Depth Filtration

- Bulk drug substance-filling capabilities

We are experts in buffer and resin screening and a full spectrum of chromatography techniques, including:

- Affinity chromatography

- Ion exchange

- Hydrophobic interaction

- Mixed-mode and MEP chromatography

- Reverse Phase

- Size Exclusion

- Charged membrane filtration

Our downstream process development also focuses on impurity clearance and aggregate reduction strategies such as host cell protein (HCP) clearance, viral clearance studies and process yield optimization. Chromatography resin dynamic binding capacity studies. Chromatography resin lifetime, cleaning and aging studies. Clarification development and optimization. Design Scale down model for process characterization for better understanding and control of manufacturing processes to ensure efficiency and assurance of consistent process performance.

Purification Development for Clinical and Commercial Readiness

Our purification methods are designed to evolve with your program. We perform all the BLA enabling activities including Pre-Performance Qualification (PPQ) to define critical process parameters, optimize process conditions, and set acceptance criteria for validation. By Phase III, your purification process will be fully characterized and ready for tech transfer to commercial production at our cGMP manufacturing facility.

Viral Clearance Studies and Filtration Support

To ensure safety and compliance, GBI provides comprehensive viral clearance study management in partnership with leading biological safety testing organizations. Our services include:

- Low pH and chemical inactivation methods

- Nanofiltration

- Chromatography-based virus removal

We compile full viral clearance study packages with scale-down validation to support regulatory submissions. Throughout the process, we ensure that your process is faithfully represented and executed by providing you with direct access to an on-site scientific liaison at the testing organization.

Aggregate Removal Development and GMP Manufacturing for a Conjugated Theranostic Product

DownloadYour Partner in Scalable Downstream Processing

From upstream processing to final purification development and manufacturing of the drug substance and drug product, GBI delivers high-quality, end-to-end biologics manufacturing solutions. As a cGMP manufacturer and one of the most experienced CDMO companies in the US, we can help you bring your biologic therapies from early-phase studies to commercial success.

Contact us today to learn more about our downstream process purification capabilities.